Okotoks conducted a multi-facility energy efficiency retrofit in 2014, which included their Recreation Centre, Centennial Arena, and Fire Hall. With operational cost savings expected to be as high as $50,000 per year, the payback period be only 6.7 years. The project will also save the Town 4,268 GJ of energy and 327 tonnes of GHG emissions per year.

Fire Hall

Updates in the Fire Hall included replacing existing incandescent and T8 fixtures with LED lighting, installing low-flow shower heads. Additionally, the ventilation system was converted from a constant air supply to a demand controlled system. CO2 sensors were installed to monitor occupancy and to modulate incoming air accordingly, reducing energy consumption.

Centennial Arena

In the Centennial Arena, the focus was on optimizing existing systems to improve building performance. For instance, the heat recovery unit was adjusted to shut down during unoccupied periods, the temperature of water used to resurface the ice was reduced from 81º to 65ºC, and the ice temperature set point can be adjusted for different activities to reduce refrigeration run time. Sixty-seven 400W metal halide lights over the ice pad were also replaced with 205W LED fixtures.

Recreation Centre

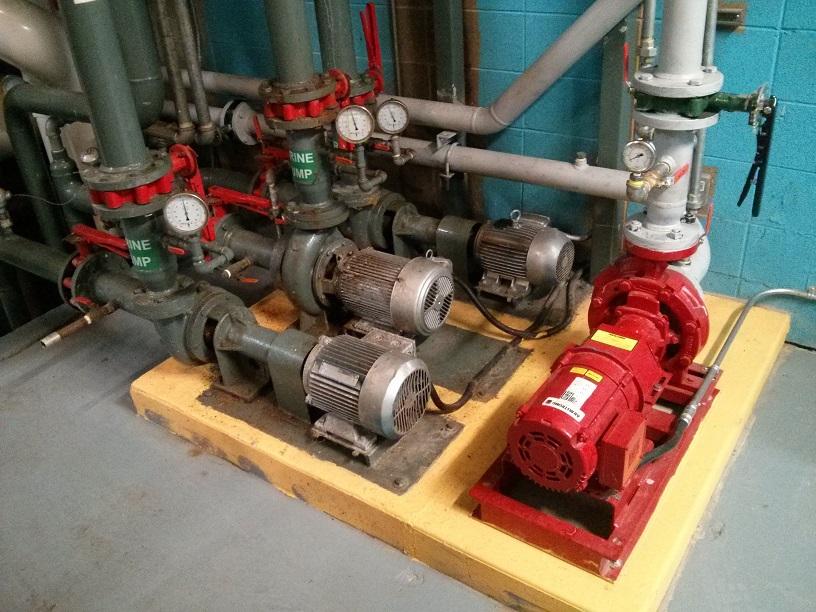

Similarly to the Centennial Arena, many of the energy conservation measures implemented in the Recreation Centre were recommissioning projects. Building management system parameters were adjusted in order to reduce the operating schedule of the heating and ventilation systems during unoccupied periods. The solar wall was also recommissioned to assist in preheating the outside air used to control humidity in the spaces adjacent to the pool. A heat recovery unit was also installed to capture waste heat from the refrigeration plant in order to melt snow in the melt pit, and existing 250W metal halide lights in the pool area were also replaced with dimmable 136W LEDs.

You must be logged in to post a comment.